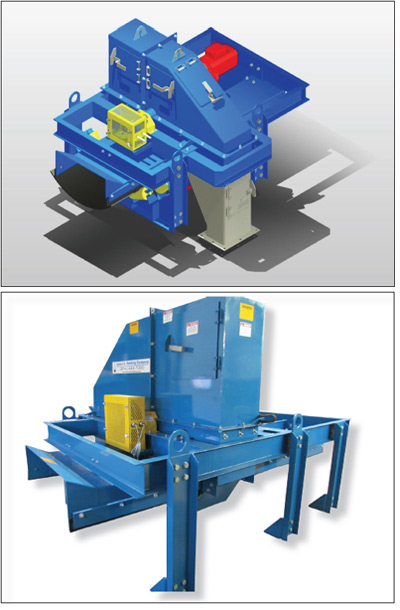

“Nine-Iron” Swing Samplers

How the “Nine-Iron” Swing Sampler Works:

The counterweighted, stainless steel cutter rests at its normal parked position, just off the edge of the customer’s conveyor belt. When activated, the electromechanical drive rotates the cutter through its swing in a perfect arc, extracting a cross-sectional sample cut that represents the material on the moving belt. A wiper blade mounted on the rear of the cutter and (2) two contour idlers adapt the customer’s belt to the cutter’s radius to help ensure that all sampled material is deposited into the stainless steel sample chute. The cutter follows through and is stopped by the brake motor in its original parked position, just off the edge of the conveyor belt. This stopping point ensures that all the primary sample is ejected into the stainless steel sample chute. A unique control design, using two targets and two proximity switches, facilitates stopping the cutter at the proper position, while ensuring that the cutter does completely exit the conveyor belt.

The “Nine-Iron” Sampler Features and Benefits

- Models for all belt sizes

- User friendly sampling

- Minimal system height

- Easy retrofit

- Flexibility

- Low cost